Osotech Sp. z o.o. is a second generation family business founded in 1982. We specialize in production of parts and components for the automotive industry and other industries using a modern machine park. We operate on the market following a traditional business model – establishing direct and long-term relationships with our clients.

Currently our team is made of 86 members – 65 of them are directly involved in the production process.

We are continuously committed to raising the standards of our operation as regards customer service, technical support and innovative services. We are a company with a reputation of good quality products and reliability in terms of order lead times, which was confirmed, among others, by ISO 9001-2000 quality certificate granted in March 2006. We were recertified in subsequent years pursuant to ISO 9001:2008 and ISO 9001:2015.

Following the requirements of PN-EN ISO 9001:2015 and PN-EN ISO 14001:2015, we implemented an Integrated Management System in 2019. The IMS covers the production of parts and components for the automotive industry. Successful results of audits oblige us to constantly monitor, measure and analyse our processes in order to continuously improve them. The IMS covers all activities, from the purchase of raw materials to the delivery of finished goods to our clients and the provision of services included in the scope of our technologies.

Services

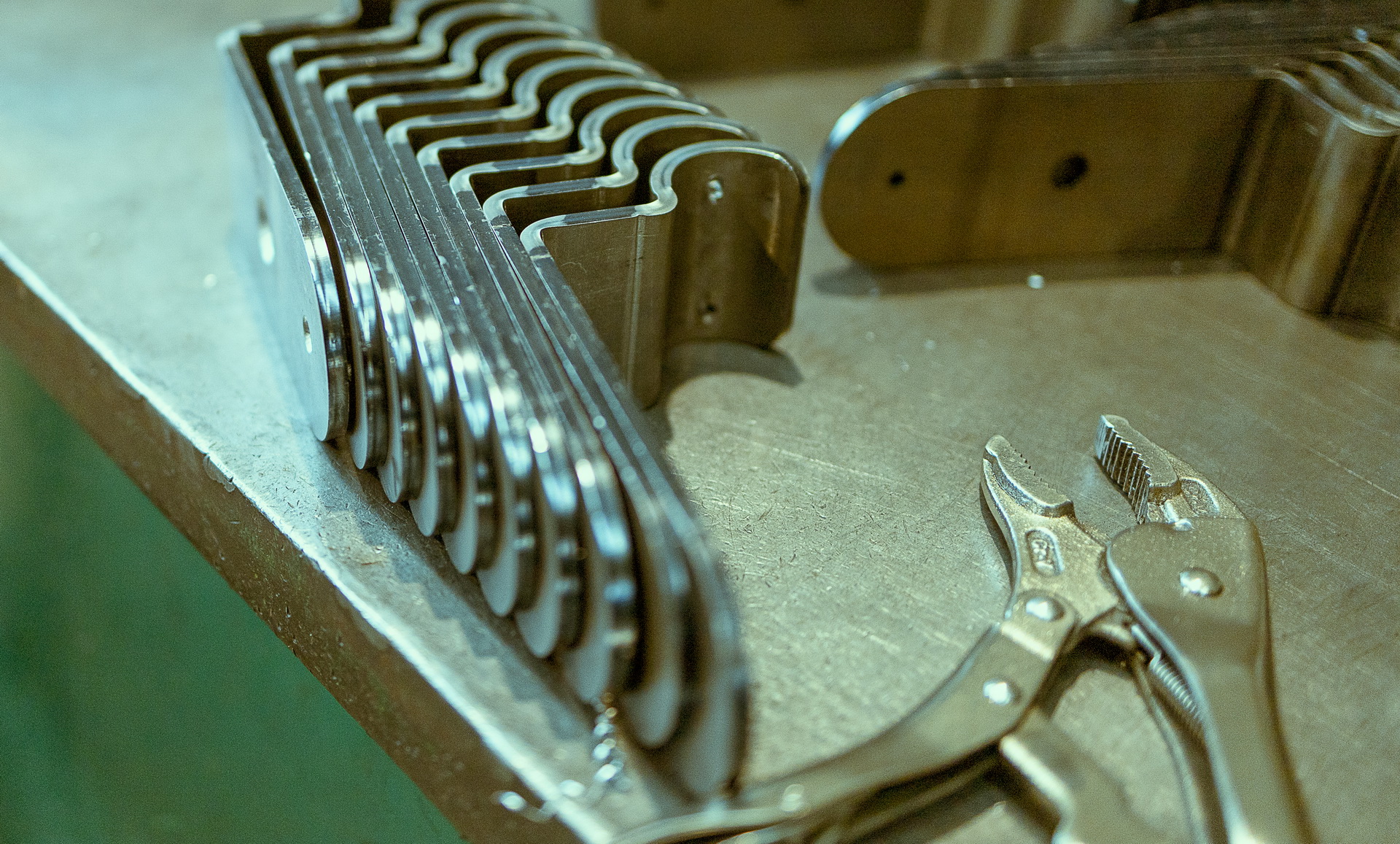

We offer highly specialized engineering services in the field of manufacturing metal parts and components for various industries. We provide services based on technical documentation submitted by a client or documentation prepared by our team in line with client’s guidelines and expectations.

We work on a modern and varied machine park that includes, inter alia, the following:

- laser burners

- hydraulic punching machines

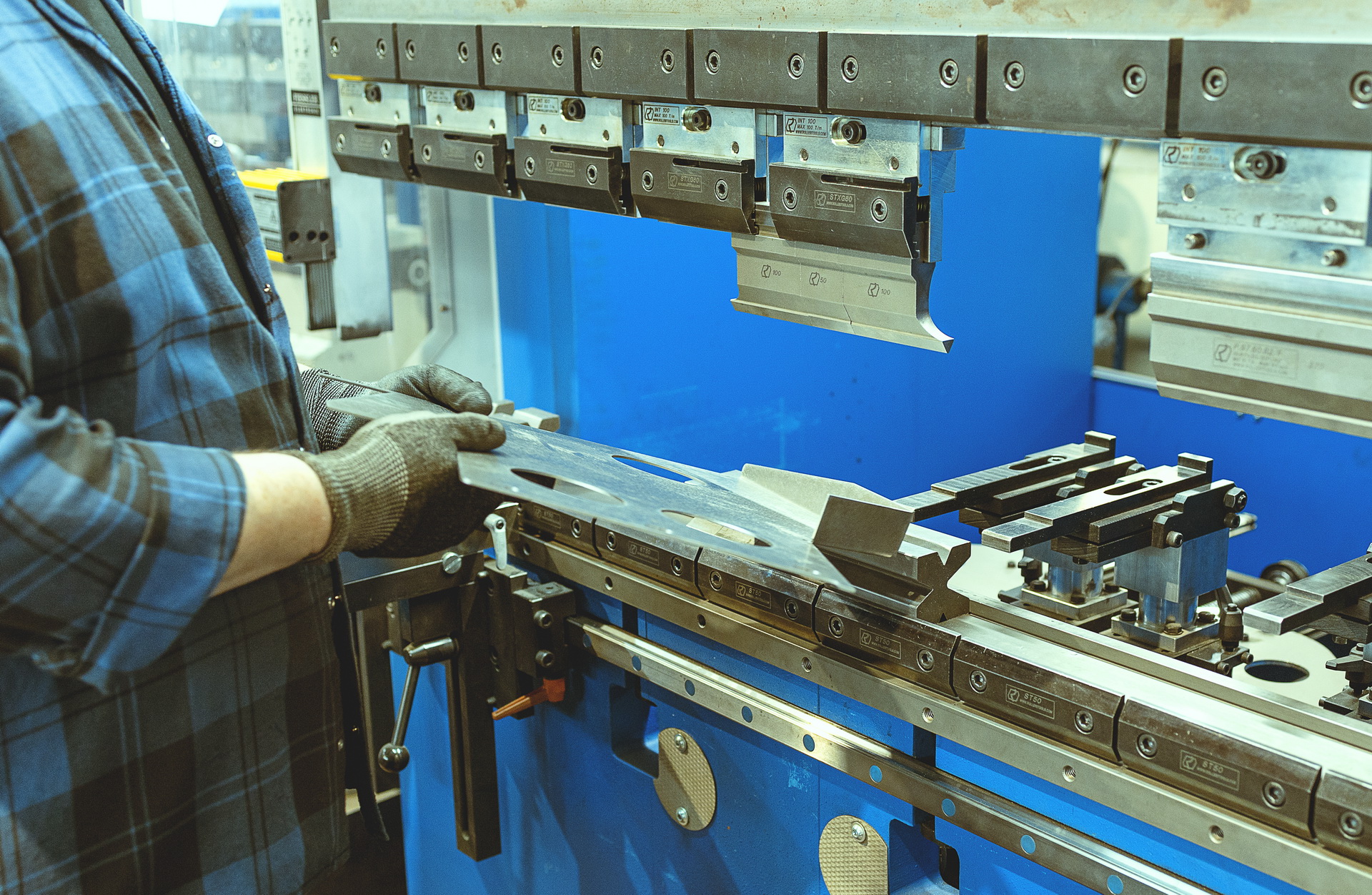

- NC bending machines

- eccentric and hydraulic presses

- saws for cutting profiles, pipes and flat bars

- pipe bending machine, rolling mills

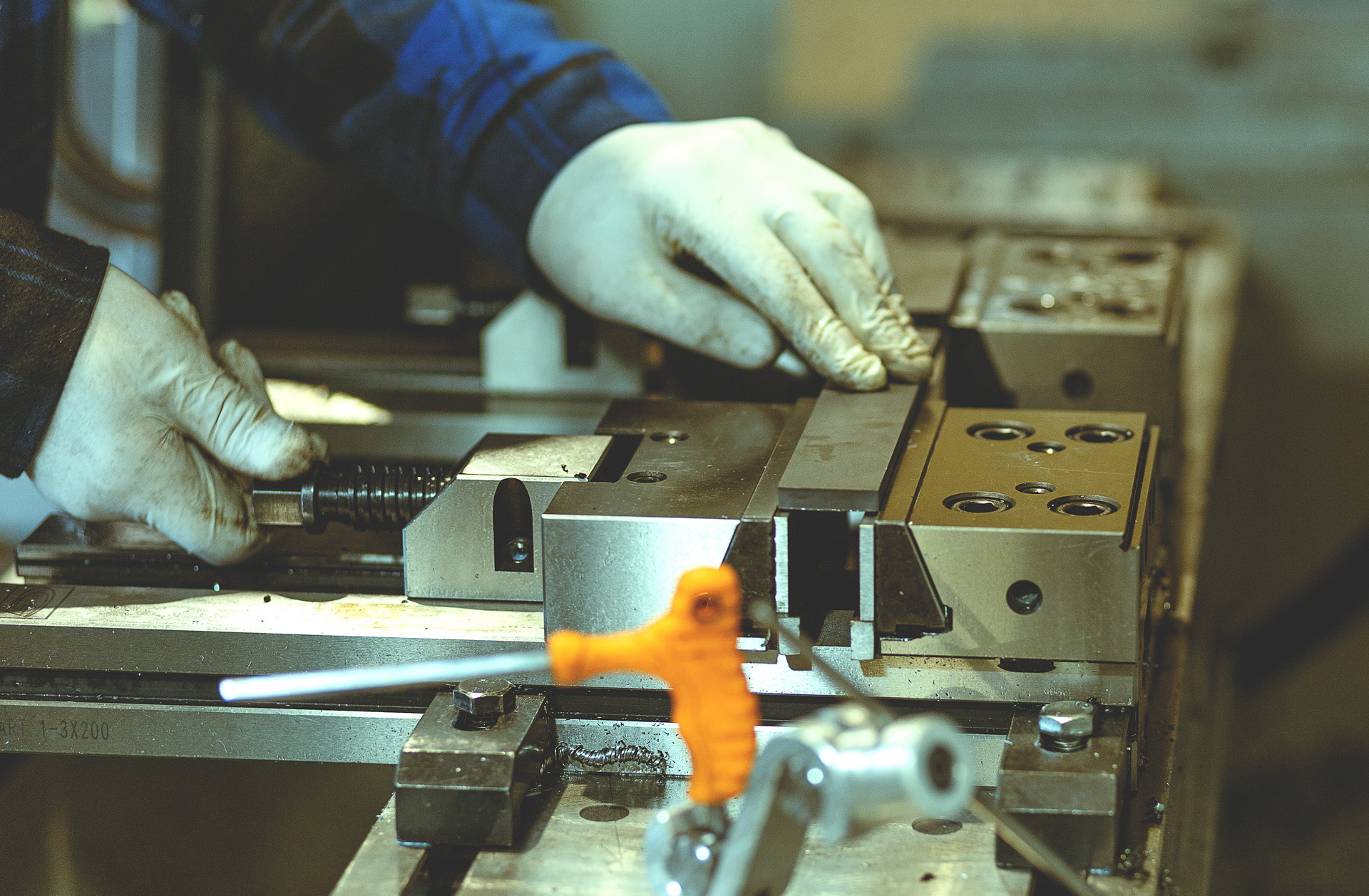

- conventional and CNC lathes, conventional and CNC milling machines, drilling machines

We offer the following engineering processes necessary to provide complex services to our clients:

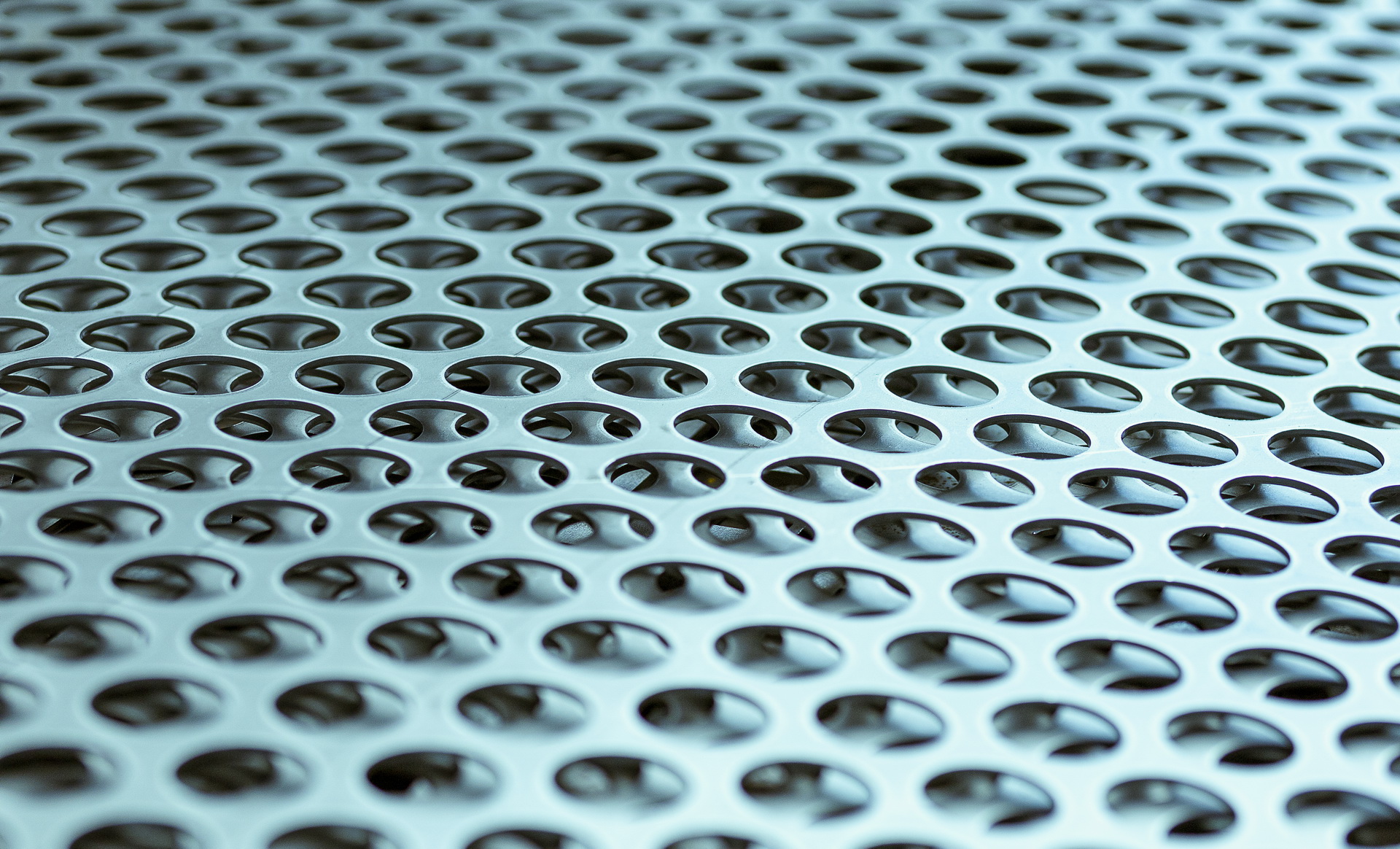

- sheet metal cutting:

- laser cutting (carbon steel up to 20 mm, stainless steel up to 8 mm, aluminium up to 8 mm, maximum sheet metal format 1.5 m x 3.0 m),

- hammer punching (material up to 3 mmm thick, maximum sheet metal format 1.5 m x 3.0 m)

- cutting rods, pipes, profiles and sections with band saws

- machining – turning and milling

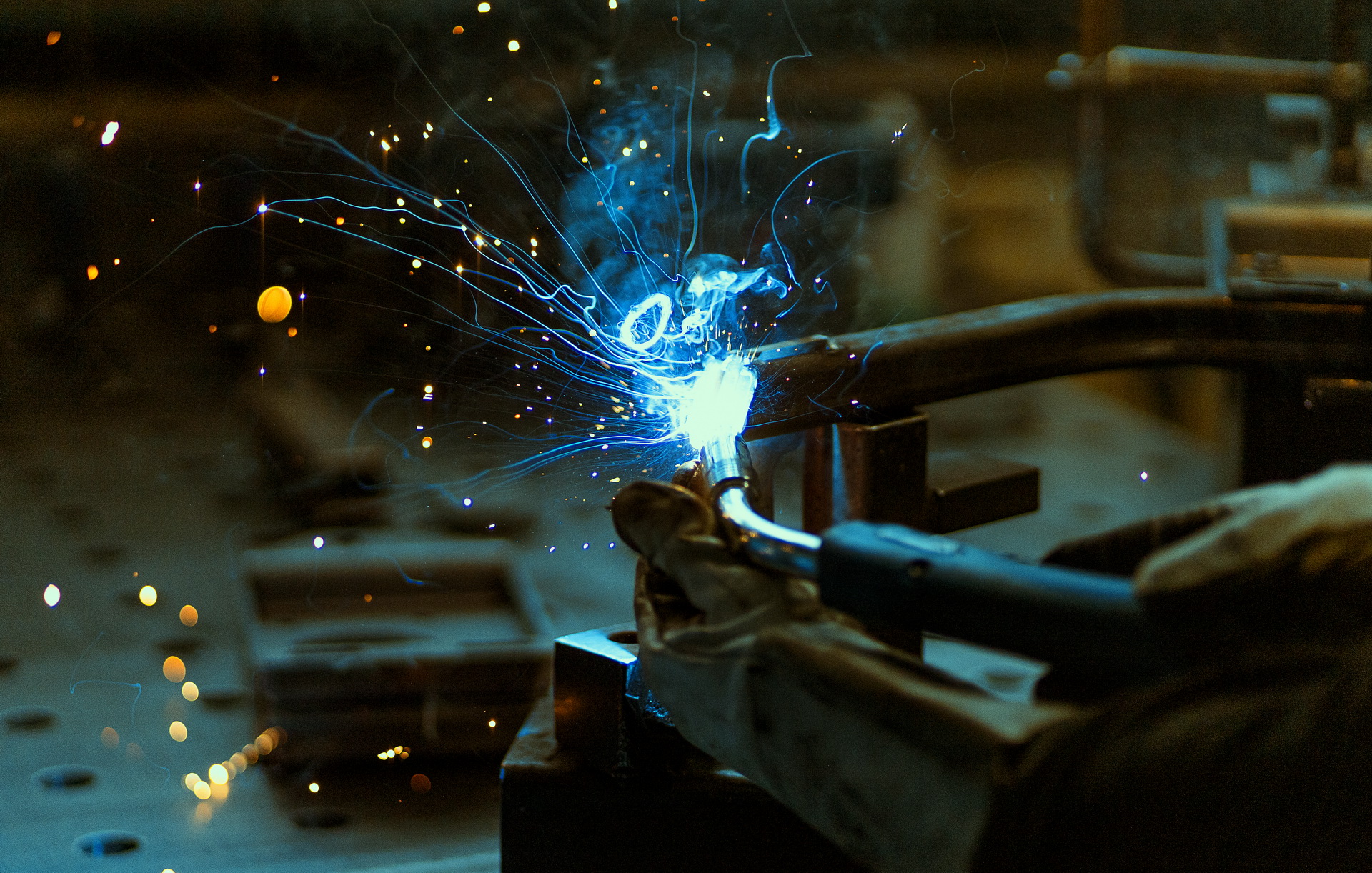

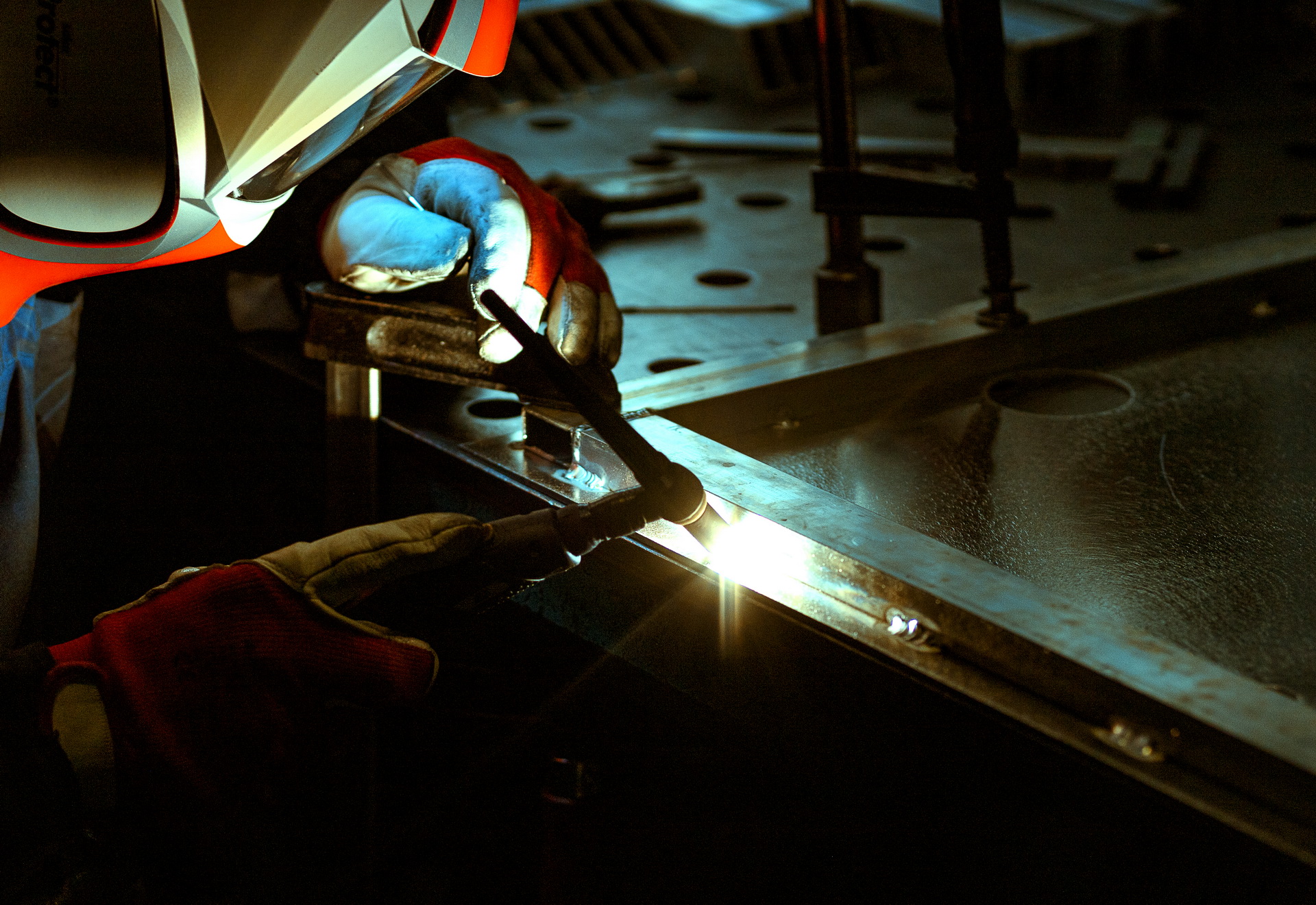

- carbon steel, stainless steel and aluminium welding

- metal processing

- edge bending (maximum edge length 3 m, material thickness up to 8 mm)

- bending with eccentric and hydraulic presses

- stamping

- stamping

- comprehensive locksmith machining with assembly (drilling, conventional threading, friction threading, welding of nuts and dowels, assembly of rivet nuts and push-in studs, etc.)

We mainly work with carbon steel, stainless steel and aluminium. However, if our clients have other expectations and needs, we manufacture bronze, copper and brass products.

Our technological processes include powder coating, zinc galvanizing, hot-dip galvanizing, anodizing, KTL and other coatings such as zinc-aluminium, nickel-aluminium.

We remain open to any cooperation and taking up new challenges!

Products

Our product portfolio includes:

- parts and components for bus production (emergency doors, steps/stairs, wheel arches, radiator covers and mounts, engine suspension brackets, chassis suspension components, bumpers, gearbox mounts, battery drawers, muffler elements, flaps, clamps and others)

- road equipment (road sign brackets and fixings, emergency lamp brackets and trusses, portable road sign bases, roadside barriers connectors)

- elements of seats used in public transport vehicles

- other metal elements manufactured in line with client’s documentation, requirements and needs

Our Clients

We provide services for the companies from the following industries and business sectors:

automotive

rail transport

arms industry

furniture

agriculture

construction

Industry 4.0

We are currently working on implementing Industry 4.0 technology and complex digital transformation – more information soon

Suppliers

Quality is an important factor ensuring conformity of our products with Customers’ requirements. Bearing that in mind, we strive to continuously improve our processes and processes in the supply chain. Therefore, we kindly ask you to read the following documents:

Next, could you please complete the survey regarding the level of sustainable development and send it to: saq@osotech.pl